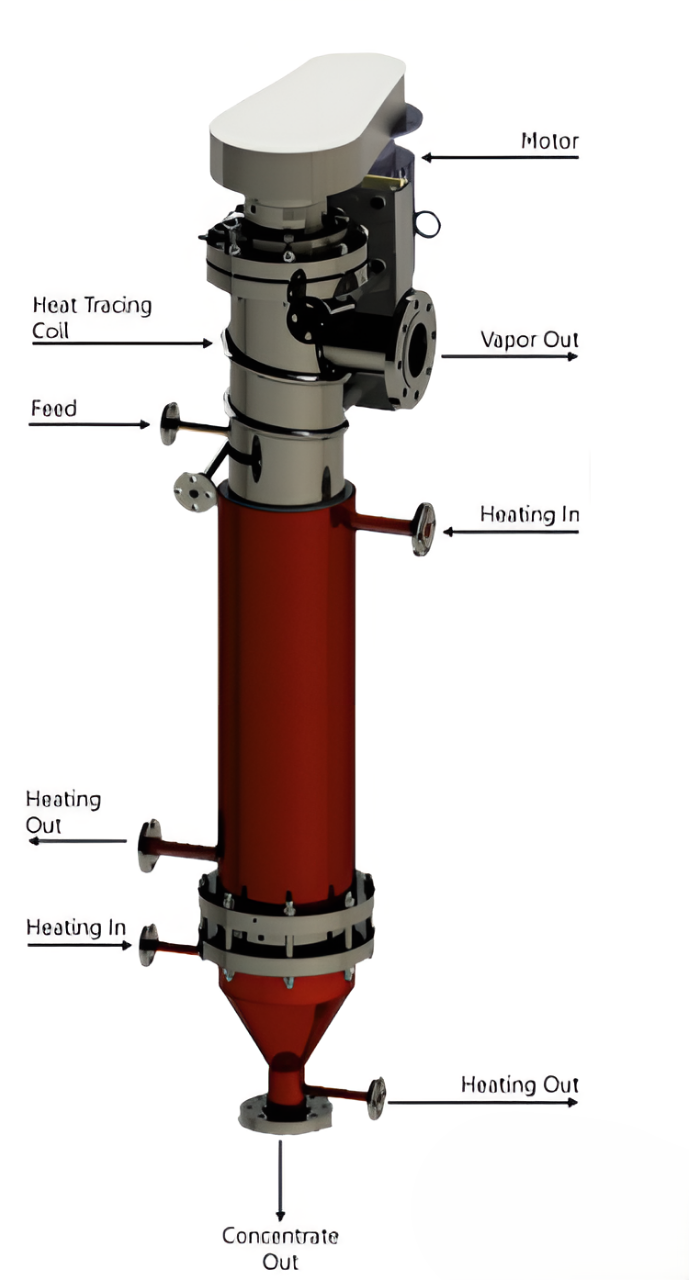

Agitated Thin Film Evaporator (ATFE)

A Thin Film Evaporator (TFE) consists of two major assemblies – a jacketed shell and a rotor assembly which rotates at high speed inside the shell. The rotor blades spread the feed evenly on the heated surface into a thin film and further agitate the film.

Features

- Low Residence Time.

- Once through pass without recirculation.

- Localised heat transfer coefficient reduction is avoided by giving the intense agitation, thus avoiding scaling.

- Product hold-up is low.

Applications

- Vacuum distillation of bulk drugs, intermediates, fine chemicals, glycols, used lubricating oils, fatty acids and their derivatives, rubber chemicals, amines, and esters.

- Recovery of contaminated solvents and products from residue.

Manufacturing Capability

- Capacity Offered: 0.005 m2 to 7.5 m2.

- Designed to operate at a wide range of temperatures, i.e., 30°C to 150°C.

- Designed to withstand a pressure of Full Vacuum to 2 bar(g).

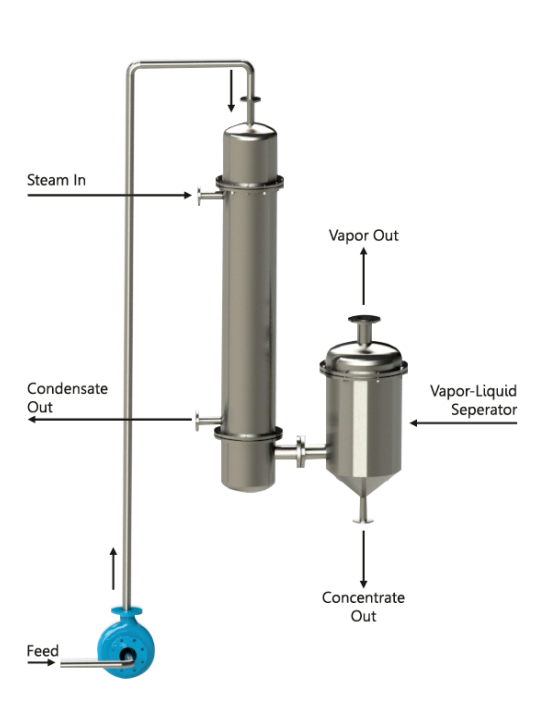

Falling Film Evaporator(FFE)

A FFE is a vertical shell and tube type heat exchanger. The liquid to be concentrated is fed at the top of the heated tubes and distributed in such a way that it flows down on the insi surface of the tubes as a thin film. As the film gets heated, the vapors generate co-currently.

Features

- Ideal for heat sensitive material.

- Short residence time.

- The Delta T between process and utility can be handled at low values.

Applications

- Recovery of solvents in the chemical industry.

- Concentrating the bulk products.

- Used as a reboiler to a distillation assembly.

- For purification of biodiesel.

Manufacturing Capability

- Capacity Offered by us : 0.5 m2 to 50 m2.

- Designed to operate at wide range of temperature i.e 30°C to 200°C

- Designed to withstand a pressure of Full Vacuum to 2 bar(g).

- Can be fabricated in SS304, SS316, HC-22 & HC-276.

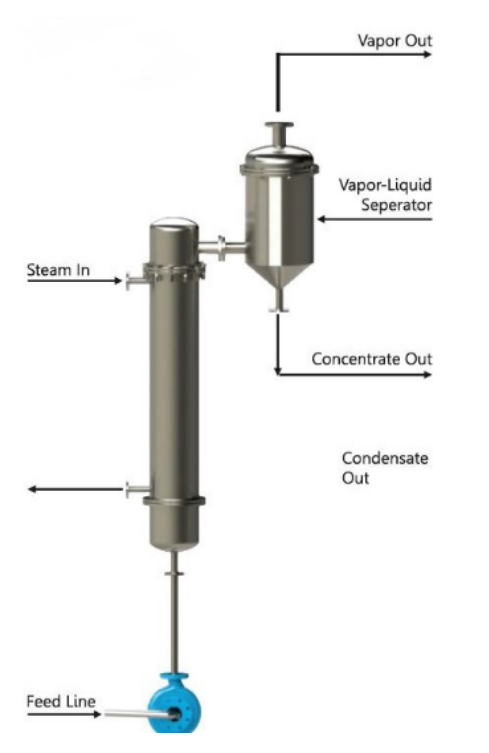

Rising Film Evaporator(RFE)

A RFE is a vertical shell and tube heat exchanger. The liquid to be concentrated is fed at the bottom of the heated tube bundle. As the liquid feed receives the heat, the vapors generated lift the liquid upwards. The velocities generated by the vapor lift are quite high, giving good thermal performance.

Features

- Capable of handling fouling liquids.

- Steam economy is improved by using Multiple effect arrangement thus saving the product cost.

- Trace quantities of suspended particles in feed are tolerated.

Applications

Concentration of dilute solutions containing water and organic solvents in applications such as:- Plant extracts in water or organic solvents.

- As a reboiler to distillation column.

Manufacturing Capability

- Capacity Offered: 0.005 m2 to 7.5 m2.

- Designed to operate at a wide range of temperatures, i.e., 30°C to 200°C.

- Designed to withstand a pressure of Full Vacuum to 2 bar(g).

- Can be fabricated in SS304, SS316, HC-22 & HC-276.