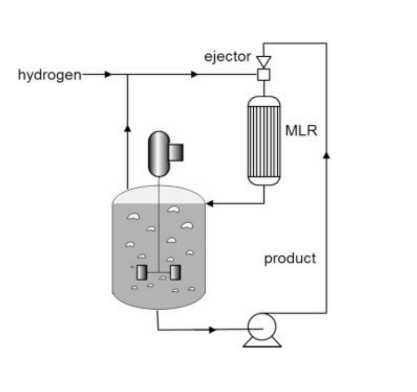

Loop Reactors

A loop reactor is a continuous steel tube or pipe which connects the outlet of a circulation pump to its inlet. Reactants are fed into the loop where the reaction occurs, and the product is withdrawn from the loop.

Features

- Overcomes mass transfer easily between gas and liquid.

- Lower foot prints.

- Operate in Semi batch or continuous mode.

Applications

- Used in chlorination, ethoxylation,hydrogenation and polymerization.

- For reducing the batch cycle time of gas-liquid interacting system.

Manufacturing Capability

- Capacity Offered by us : 0.5 Ltr to 50 Ltr

- Designed to operate at temperature of 200 °C

- Designed to withstand a pressure of 20 bar(g)

- Can be fabricated in SS304, SS316, HC-22 & HC-276

Autoclaves / Pressure Reactors

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure/temperature.

Features

- Lower footprints.

- Geometrical similarities to that of scaled-up commercial reactors.

- Easy plug-in and plug-out laboratory and pilot units.

Applications

- Used in a variety of chemical industries for carrying out unit processes under pressure.

- Can operate in batch or semi-continuous mode to produce finished or intermediate products in various chemical industries.

- Used in reactions like ammonolysis, hydrogenation, etc.

Manufacturing Capability

- Capacity Offered by us: 0.1 Ltr to 100 Ltr

- Designed to operate at a temperature of 300 °C

- Designed to withstand a pressure of 100 bar(g)

- Can be fabricated in SS304, SS316, Inconel, HC-22 & HC-276